3D printing has revolutionized the way manufacturers create products and has opened up a world of possibilities for businesses. As a result, the demand for 3D printing materials has increased exponentially, and polymers have become a popular choice for 3D printing materials. In this article, we will explore the role of polymers in 3D printing industries and how they are changing the landscape of manufacturing.

What are Polymers?

Polymers are long-chain molecules composed of smaller units called monomers. These monomers can be either natural or synthetic and are connected together in various ways to form a range of different materials with unique properties. Polymers are used in a variety of industries for a wide range of applications, including 3D printing.

Advantages of Polymers in 3D Printing

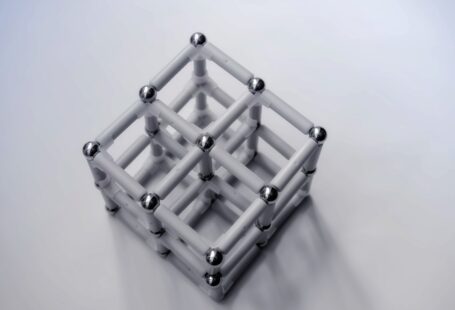

Polymers have a number of advantages when used in 3D printing. Firstly, they are lightweight and easy to extrude. This makes them ideal for 3D printing, as the layers can be quickly and easily built up, resulting in faster production times. Additionally, polymers are highly durable and can withstand high temperatures, making them suitable for use in industrial 3D printing.

Types of Polymers Used in 3D Printing

The most common type of polymers used in 3D printing are thermoplastics. These are polymers that can be heated and cooled repeatedly without losing their shape or structure. Common thermoplastics used in 3D printing include ABS, PLA, and nylon. Additionally, there are also thermosetting polymers, which are polymers that become permanently hardened when exposed to heat and cannot be reheated and re-formed.

Applications of Polymers in 3D Printing Industries

Polymers are widely used in 3D printing industries for a variety of applications. The most common application is rapid prototyping, where manufacturers use polymers to quickly and cost-effectively create mockups and prototypes of products. Additionally, polymers are used for small-scale production runs, such as creating parts for medical devices or automotive components.

Conclusion

Polymers have become an essential part of the 3D printing industry, offering manufacturers a variety of advantages. Polymers are lightweight, durable, and easy to extrude, making them ideal for rapid prototyping and small-scale production runs. With the increasing demand for 3D printing materials, polymers have become an indispensable part of the industry and are set to continue playing a major role in the future.