The use of polymethyl methacrylate (PMMA) in 3D printing is becoming increasingly popular due to its versatility and affordability. PMMA is a type of thermoplastic that is used to create objects through a process known as additive manufacturing, or 3D printing. It has a variety of applications, from prototyping to manufacturing production parts. PMMA is a strong, lightweight, and easy to use material for 3D printing.

Benefits of Using PMMA in 3D Printing

PMMA is an ideal material for 3D printing due to its numerous advantages. The most significant benefit is that it is easy to use. PMMA is a thermoplastic, which means it can be melted and formed into any shape. This makes it perfect for creating complex shapes and intricate details that are not possible with traditional manufacturing processes.

PMMA is also an affordable material, making it ideal for prototyping and small production runs. It is also strong and lightweight, which makes it suitable for a variety of applications. Another benefit of PMMA is that it is resistant to chemicals and heat, making it suitable for a range of industries.

Applications of PMMA in 3D Printing

PMMA is used in a variety of 3D printing applications, from prototyping to manufacturing production parts. It is often used for creating prototypes, as it is fast and easy to use. PMMA is also used for creating small production runs, as it is an affordable material. Additionally, it is often used for creating models and molds for industrial applications.

PMMA is also used for creating functional parts, such as parts for medical devices, electronics, and automotive components. It is also used for creating medical implants, as it is biocompatible and can be sterilized. Furthermore, PMMA is used for creating consumer products, such as toys and figurines.

Common Challenges of Using PMMA in 3D Printing

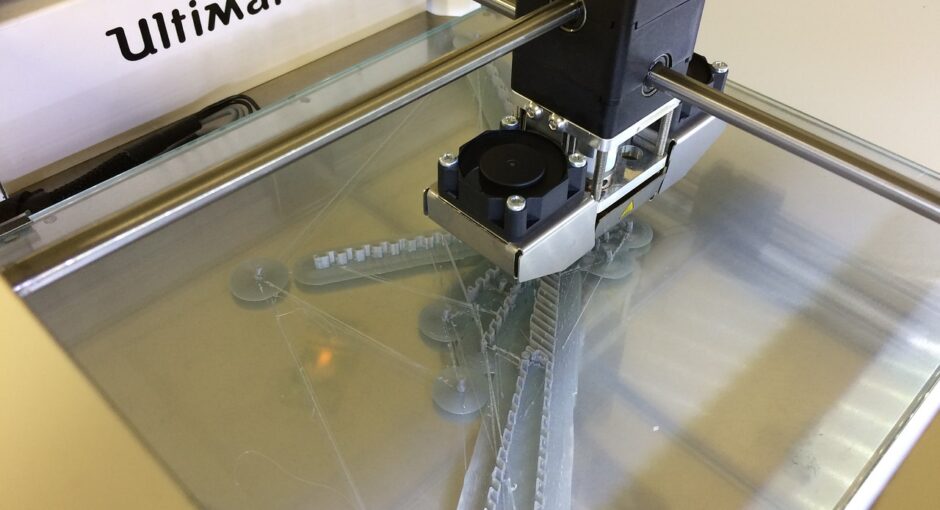

Although PMMA is a versatile material for 3D printing, it does have some drawbacks. One of the most common challenges is warping, which is caused by uneven heat distribution during the printing process. Warping can be prevented by using a heated bed and by using a cooling system to keep temperatures consistent during the printing process.

Another challenge with PMMA is that it is brittle and can break if not handled carefully. It is also prone to cracking if subjected to sudden temperature changes. Additionally, it is difficult to finish, as it is not compatible with many post-processing techniques, such as sanding and painting.

Conclusion

PMMA is a versatile and affordable material that is ideal for 3D printing. It is easy to use and has a variety of applications, from prototyping to manufacturing production parts. However, there are some challenges associated with using PMMA, such as warping and brittleness. Nonetheless, PMMA is a great material for 3D printing and is becoming increasingly popular due to its numerous advantages.