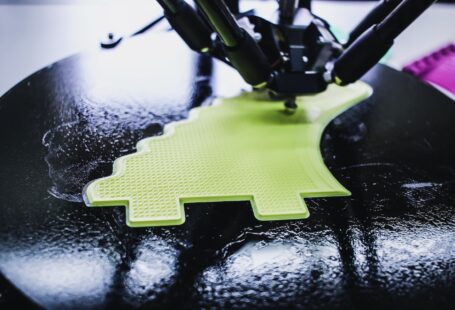

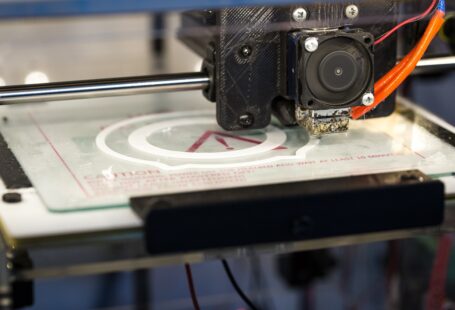

The use of copper in 3D printing is becoming increasingly popular. Copper offers a variety of unique benefits that can make it a viable option for 3D printing. It is a strong and durable material that is heat resistant and can be used in a wide range of applications. It is also relatively inexpensive and has a high melting point, making it an attractive option for 3D printing.

Benefits of Copper for 3D Printing

The use of copper in 3D printing offers a number of benefits that make it an attractive option. First, copper is strong and durable, making it suitable for a wide range of 3D printing applications. It is also heat resistant, which is important for applications such as automotive or aerospace parts. Copper is also relatively inexpensive compared to other materials, making it a good option for those looking for an affordable 3D printing material. Finally, copper has a high melting point, which is important for 3D printing projects that require high-temperature printing.

Uses of Copper for 3D Printing

Copper can be used for a variety of 3D printing applications. It can be used to create intricate shapes and designs, as well as for larger items such as automotive or aerospace parts. Copper is also suitable for medical and dental applications, as well as for creating electronics and other components. It can also be used for prototyping and short-run production runs.

Limitations of Copper for 3D Printing

Despite its many benefits, copper does have some limitations when it comes to 3D printing. It is not as easy to machine as other materials, such as aluminum or steel. It also has a relatively high melting point, which can be a problem when it comes to printing with higher temperatures. Finally, copper is not as easy to work with as other materials, such as plastic or nylon.

Conclusion

In conclusion, copper has a number of benefits that make it a viable option for 3D printing. It is strong and durable, heat resistant, and relatively inexpensive. It can be used for a variety of 3D printing applications, including automotive and aerospace parts, medical and dental applications, and prototyping and short-run production runs. However, it does have some limitations, such as its high melting point and the fact that it is not as easy to machine as other materials. Despite these limitations, copper is an attractive option for 3D printing and is becoming increasingly popular.